| Availability: | |

|---|---|

| Quantity: | |

B-912G

GAOFE

The B-912G Flame Retardant PET Label is engineered for industries where fire safety, durability, and reliable traceability are critical. Made of premium polyester film with a flame-retardant coating, it complies with UL94 VTM-0 standards and offers outstanding heat, chemical, and abrasion resistance. With strong adhesion and compatibility with thermal transfer printing, B-912G provides long-lasting identification for harsh industrial and automotive environments.

Flame Retardant Certified – Meets UL94 VTM-0, suitable for safety-critical industries.

High Durability – PET film resists tearing, abrasion, and mechanical stress.

Heat & Chemical Resistance – Withstands high temperatures, oils, solvents, and industrial chemicals.

Strong Adhesive Bonding – Reliable adhesion to metals, plastics, and painted surfaces.

Thermal Transfer Printing – Delivers sharp, durable print quality resistant to fading.

Long-Term Reliability – Ensures stable identification throughout product lifecycle.

Control Panels & PLCs – Labels for buttons, indicators, and ports with resistance to wear, oils, and solvents.

Motors & Drives – Durable nameplates, wiring diagrams, and parameter labels with high temperature tolerance.

Sensors & Instruments – Environmental-resistant identification and warning labels.

Factory Equipment Asset Tracking – Flame-retardant asset and maintenance labels for long-term use.

Automotive Electronics – Identification, certification, and traceability labels for ECUs, sensors, harnesses, and fuse boxes.

Engine Compartment – Heat-resistant component ID and warning labels for >150°C environments.

New Energy Vehicles (EV/HEV) – High-voltage safety warning labels, parameter, and traceability labels for battery packs, controllers, and charging systems.

Rail Transit – Flame-retardant labels for control panels and electrical cabinets, compliant with EN 45545.

Onboard Electronics – Identification labels inside avionics and electrical systems, meeting FAR 25.853 flame retardancy and low smoke/toxicity requirements.

Optimal Printing Solutions

1.Recommended Ribbons:

Resin Thermal Transfer Ribbons

Model:TR4032 Resin Ribbon

Features:

High Resolution Printing:

Designed for high-definition printing, it accurately reproduces fine text, complex graphics, and high-density barcodes (e.g., Data Matrix, QR codes). Typically supports 300dpi or even 600dpi resolution, ensuring high barcode scan rates and readability.

Excellent Fade Resistance:

Printed content fades significantly slower than wax-based or hybrid ribbons during long-term use or exposure to light.

2.Recommended Printers:

Model:TSC MH641 Printer

Features:

Print speed up to 300mm/s, ideal for mass production lines – significantly boosts efficiency.

Industrial-grade metal frame supports 24/7 continuous operation with robust stability.

Other Option

| No. | Type | Model |

| 1 | Flame retardant nylon cloth labels | GF-766 |

Specification

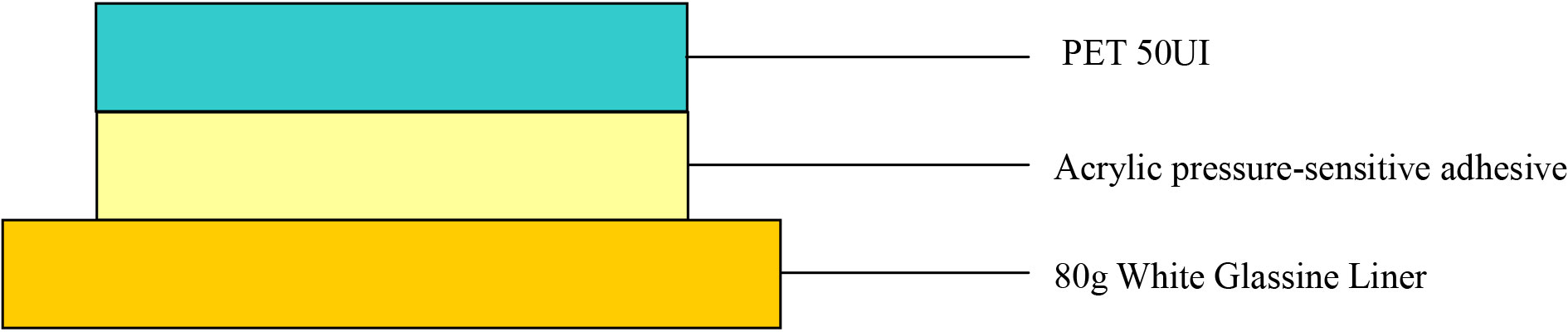

| MATERIAL NAME | 50# Bright White PET (TW - 050) |

| ARTICLE CHARACTER | PET |

| BASIC WEIGHT | 0.050±0.005 mm |

| FIXED AMOUNT | 70±5 g/ |

| THE MOLD SLICES FUNCTION | Good die - cutting performance |

| PRINTING FUNCTION | Good printability |

| COLOR | Matt White |

| BAR CODE | OK |

| SMOOTHNESS | Good |

| WEATHER RESISTANCE | OK |

| TEMPERATURE RANGE | - 20 - 120℃ |

| SURFACE ENERGY | 38D↑ |

| DIAPHANEITY | Opaque |

| ELECTROPLATE STRENGTH | — — |

| ADHESIVE | Pressure - sensitive adhesive (ZXPQN - 73) |

| ADHESIVE BASE | Solvent - based adhesive |

| BASIC WEIGHT | 0.020±0.002 mm |

| FIXED AMOUNT | 20±2 |

| TACK | 3 ↑ |

| COHESION FORCE | 24 ↑ |

| STAINLESS STEEL ADHESION | 8 ↑ |

| PP ADHESION | — |

| GLASS ADHESION | — |

| RE - ADHESIDUAL | — |

| SERVICE TEMPERATURE RANGE | 120℃ |

| TEMPERATURE RANGE | -20 - 120℃ |

| MATERIAL NAME | 80g White Glassine (102) |

| ARTICLE CHARACTER | Semi - transparent release paper |

| BASIC WEIGHT | 0.070±0.005 mm |

| FIXED AMOUNT | 80±5 |

| LINER RELEASE | 2-10 |

| DIE CUTTING | Good |

| PRINTING FUNCTION | — |

| SMOOTHNESS | Good |

| COLOR | White and semi - transparent |