Overview

The B-912G is a premium flame retardant white polyester (PET) label engineered specifically for demanding electronics and electrical applications where safety is paramount. Constructed with a durable 50# matte white PET face material and a proprietary flame-retardant acrylic adhesive, this label meets critical safety standards. It is designed to provide clear, permanent identification while offering self-extinguishing properties to help prevent the spread of flame in the event of an electrical fault or high-temperature exposure. The B-912G ensures vital information remains legible and securely in place, making it an essential component for safety compliance and equipment identification in risk-prone environments.

Features

Flame Retardant Construction: Both the face material and the adhesive are engineered for flame resistance, complying with the VTM-0 flammability rating.

High Durability: Excellent resistance to abrasion, chemicals, and moisture, ensuring long-lasting performance in tough industrial conditions.

Wide Temperature Range: Suitable for continuous use from -20°C to +120°C, stable under thermal stress.

Permanent, Secure Adhesion: Features a high-tack, flame-retardant acrylic adhesive with strong initial adhesion (Tack ≥ 3) and excellent holding power (Cohesion Force ≥ 24H), ensuring labels stay firmly attached to stainless steel and other surfaces.

Superior Printability & Die-Cutting: Provides a smooth, opaque white surface ideal for high-quality printing and precise die-cutting, ensuring clean edges and excellent barcode scannability.

Application

Safety and warning labels on electrical cabinets, control panels, and switchgear.

Identification and rating plates for transformers, motors, and power distribution equipment.

Asset tracking and certification labels in data centers and telecommunications infrastructure.

Component identification in automotive, aviation, and industrial machinery where flame resistance is required.

Permanent nameplates for laboratory and medical electrical devices.

Optimal Printing Solutions

1.Recommended Ribbons:

Resin Thermal Transfer Ribbons

Model:TR4032 Resin Ribbonhttps://www.dggaofe.com/Resin Ribbon TR4032B - Buy Resin ribbon Product on GAOFE https://www.dggaofe.com/Resin-Ribbon-TR4032B-pd551383948.html

Features:

This ribbon is highly recommended. It delivers excellent scratch and chemical resistance, along with superior print density on the matte white surface, ensuring barcodes and text remain legible throughout the label's lifecycle.

2.Recommended Printers:

Model:TSC MH641 Printer

Features:

Print speed up to 300mm/s, ideal for mass production lines – significantly boosts efficiency.

Industrial-grade metal frame supports 24/7 continuous operation with robust stability.

Other Option

| No. | Type | Model |

| 1 | Flame retardant nylon cloth labels | GF-766 |

Specification

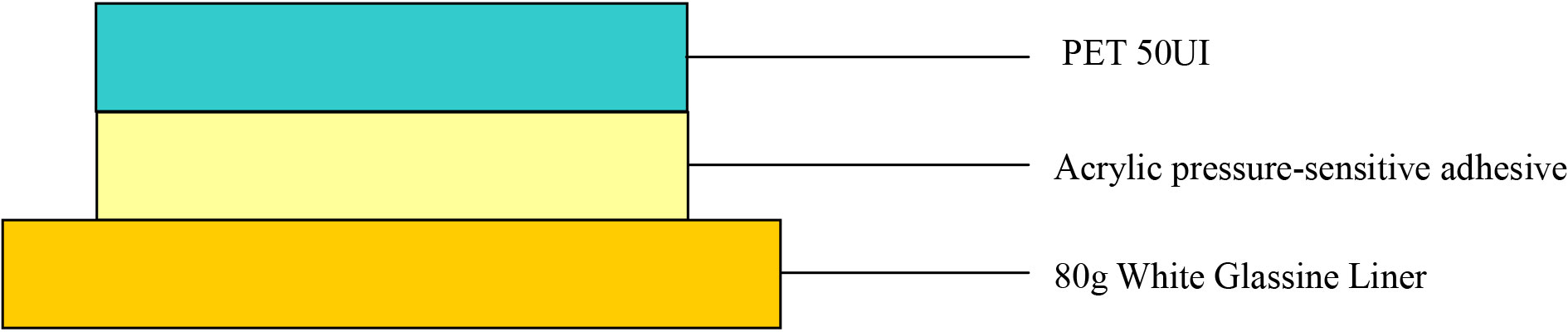

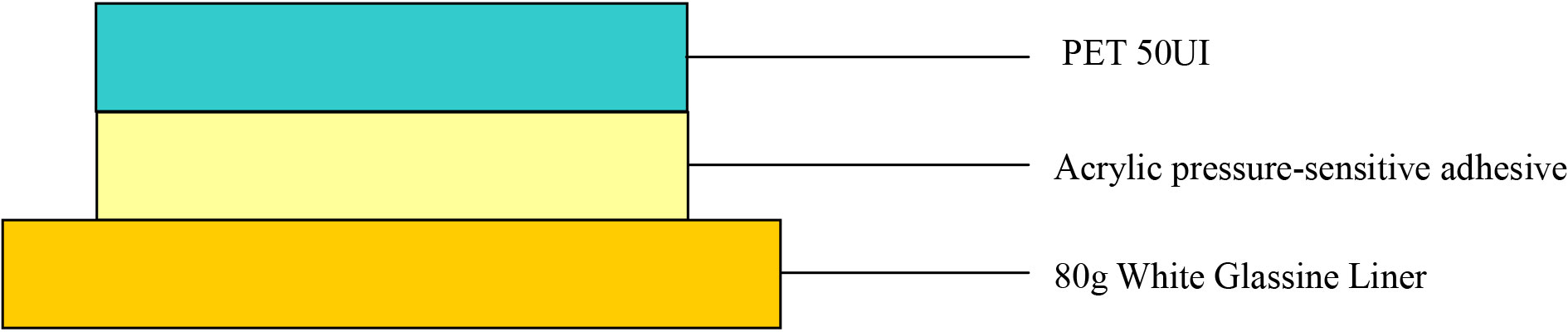

| Category | Item | Specification / Value |

| Material Structure | Face Stock | 50# Matte White Flame Retardant Polyester (PET) |

| Thickness | 0.050 mm ± 0.005 mm |

| Basis Weight | 70 ± 5 g/m² |

| Adhesive | Flame Retardant Acrylic (ZXFZR-35) |

| Thickness | 0.020 mm ± 0.002 mm |

| Basis Weight | 20 ± 2 g/m² |

| Liner | 80g White Glassine (Semi-transparent) |

| Thickness | 0.070 mm ± 0.005 mm |

| Basis Weight | 80 ± 5 g/m² |

| Performance & Physical Properties | Flammability Rating | VTM-0 |

| Service Temperature Range | -20°C to +120°C |

| Adhesion to Stainless Steel | ≥ 8 N/in |

| Initial Tack (Ball No.) | ≥ 3 (#) |

| Cohesion (Holding Power) | ≥ 24 Hours |

| Surface Energy | ≥ 38 Dynes/cm |

| Die-Cutting Performance | Good |

| Printability | Good |

| Barcode Printability | OK |

| Weather Resistance | OK |

| Storage & Standards | Shelf Life | 1 year (in sealed condition) |

| Storage Conditions | 23 ± 2°C, 65 ± 5% RH |

| Stacking Limit | Height ≤ 3m; Weight ≤ 1000 Kg/m² |

| Test Standards | Adhesion: GB/T2792-1998

Tack: GB/T4852-2002

Cohesion: GB/T4851-1998 |