Overview

B-912G PET Wire and Cable Identification Labels are engineered for applications where flame retardancy and reliable identification are critical.

Using a UL94 V-0 rated flame-retardant adhesive combined with a durable PET face material, these labels provide stable adhesion, excellent print clarity, and enhanced fire safety performance in demanding electrical and industrial environments.

Designed for wire, cable, and component identification, B-912G labels perform reliably across a wide temperature range and support automated labeling processes, making them suitable for high-volume industrial production.

Features

Flame Retardant Performance

Equipped with flame-retardant adhesive, certified to UL94 V-0 standard

Effectively reduces fire propagation risk in electrical and electronic applications

Durable PET Construction

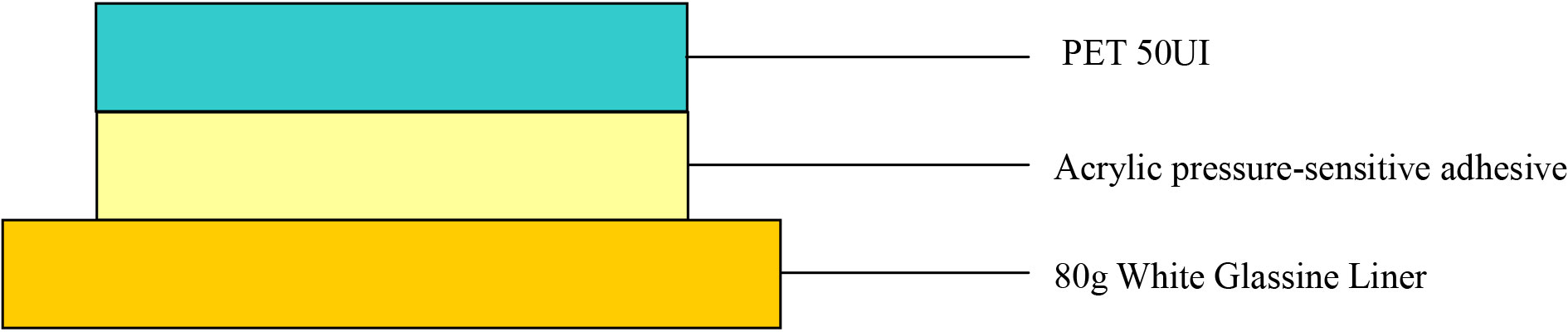

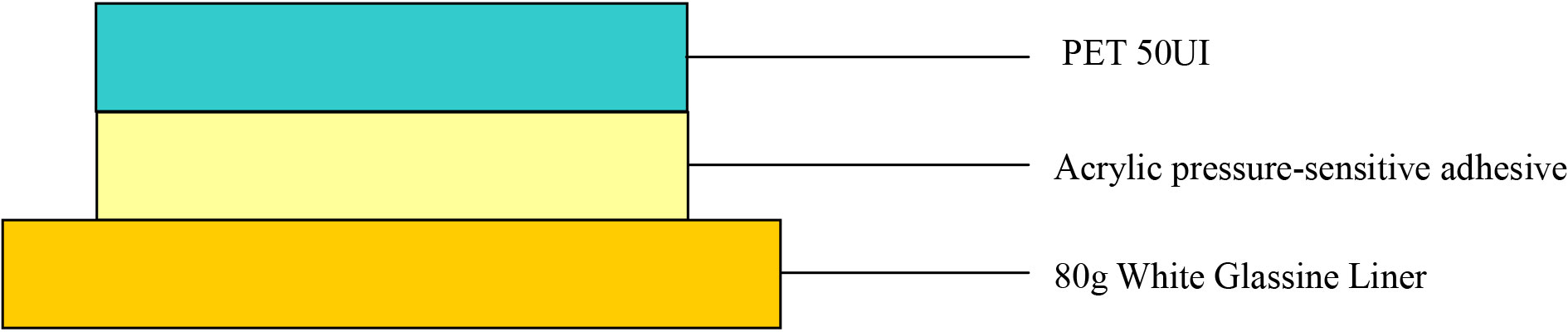

Face material: PET TW-050, approx. 50 μm thickness

Semi-transparent appearance with excellent mechanical strength and printability

Backing: 80g white glassine release liner, optimized for die-cutting efficiency

Reliable Adhesion & Mechanical Strength

Adhesive coating weight: 20 ±2 g/m²

Adhesion performance:

Steel plate ≥ 9 N/in

PP plate approx. 3 N/in

Initial tack ≥ 5#

Impact resistance ≥ 24 kgf, ensuring label integrity under mechanical stress

Wide Temperature & Processing Compatibility

Service temperature range: -20°C to 120°C

Excellent barcode readability, clean die-cut edges

Fully compatible with automatic labeling systems

Application

B-912G PET Wire and Cable Identification Labels are ideal for environments with explicit flame-retardant requirements, including:

Electrical and Electronic Equipment Identification

Wire & Cable Marking in Control Panels and Harness Systems

Automotive Parts and Wiring Harness Labels

Battery Packs and Energy Storage Components

Industrial Equipment and Safety-Critical Identification

These labels help manufacturers meet fire safety standards while maintaining long-term identification reliability.

Optimal Printing Solutions

1.Recommended Ribbons:

Resin Thermal Transfer Ribbons

Model:TR4032 Resin Ribbon

Features:

High Resolution Printing:

Designed for high-definition printing, it accurately reproduces fine text, complex graphics, and high-density barcodes (e.g., Data Matrix, QR codes). Typically supports 300dpi or even 600dpi resolution, ensuring high barcode scan rates and readability.

Excellent Fade Resistance:

Printed content fades significantly slower than wax-based or hybrid ribbons during long-term use or exposure to light.

2.Recommended Printers:

Model:TSC MH641 Printer

Features:

Print speed up to 300mm/s, ideal for mass production lines – significantly boosts efficiency.

Industrial-grade metal frame supports 24/7 continuous operation with robust stability.

Other Option

| No. | Type | Model |

| 1 | Flame retardant nylon cloth labels | GF-766 |

Specification

| MATERIAL NAME | 50# Bright White PET (TW - 050) |

| ARTICLE CHARACTER | PET |

| BASIC WEIGHT | 0.050±0.005 mm |

| FIXED AMOUNT | 70±5 g/ |

| THE MOLD SLICES FUNCTION | Good die - cutting performance |

| PRINTING FUNCTION | Good printability |

| COLOR | Matt White |

| BAR CODE | OK |

| SMOOTHNESS | Good |

| WEATHER RESISTANCE | OK |

| TEMPERATURE RANGE | - 20 - 120℃ |

| SURFACE ENERGY | 38D↑ |

| DIAPHANEITY | Opaque |

| ELECTROPLATE STRENGTH | — — |

| ADHESIVE | Acrylic (ZXFZR-35) |

| ADHESIVE BASE | Flame retardant adhesive |

| BASIC WEIGHT | 0.020±0.002 mm |

| FIXED AMOUNT | 20±2 |

| TACK | 3 ↑ |

| COHESION FORCE | 24 ↑ |

| STAINLESS STEEL ADHESION | 8 ↑ |

| PP ADHESION | — |

| GLASS ADHESION | — |

| RE - ADHESIDUAL | — |

| SERVICE TEMPERATURE RANGE | 120℃ |

| TEMPERATURE RANGE | -20 - 120℃ |

| MATERIAL NAME | 80g White Glassine (102) |

| ARTICLE CHARACTER | Semi - transparent release paper |

| BASIC WEIGHT | 0.070±0.005 mm |

| FIXED AMOUNT | 80±5 |

| LINER RELEASE | 2-10 |

| DIE CUTTING | Good |

| PRINTING FUNCTION | — |

| SMOOTHNESS | Good |

| COLOR | White and semi - transparent |