Overview

GF-766 Polyamide Film Wire and Cable Identification Labels are designed for reliable wire and cable identification in wire harness sleeving and heat shrink applications. Made from durable polyamide film, these labels maintain clear legibility and stable adhesion during harness assembly, heat shrink processes, and long-term industrial use.

They are widely used as wire harness identification labels to ensure accurate cable marking, traceability, and maintenance efficiency in complex electrical systems.

Feature

Optimized for Wire Harness Sleeving

Specifically engineered as wire and cable identification labels for wire harness sleeving, providing secure bonding and clear identification before and after sleeving installation.

Compatible with Heat Shrink Applications

Performs reliably as heat shrink wire identification labels, maintaining print clarity and material stability during heat exposure and shrinking processes.

Durable Polyamide Film Construction

Polyamide film offers excellent heat resistance and mechanical durability, making these cable identification labels suitable for demanding industrial environments.

High Print Contrast and Readability

Supports high-resolution printing for barcodes, serial numbers, and alphanumeric data, ensuring long-term legibility for cable marking labels.

Designed for Industrial Wire Identification

Ideal for use as industrial wire and cable labels in electrical assemblies requiring consistent and permanent identification.

Applications:

Wire Harness Assembly and Manufacturing

Used as wire harness identification labels for organized cable marking during harness production and assembly lines.

Heat Shrink Tubing and Sleeving Systems

Applied in heat shrink wire identification label applications where labels must withstand thermal processing and remain readable after shrinking.

Electrical Equipment and Control Panels

Supports accurate wire and cable identification labels for maintenance, troubleshooting, and system upgrades.

Industrial and Automotive Wiring Systems

Suitable for cable identification labels in industrial machinery, automotive wire harnesses, and other high-reliability electrical systems.

Optimal Printing Solutions

Recommended Ribbons:

GAOFE TR4032B resin ribbonhttps://www.dggaofe.com/Resin-Ribbon-TR4032B-pd551383948.html

Recommended Printers:

SQUIX 4 Industrial Printerhttps://www.dggaofe.com/CAB-SQUIX-4M-Industrial-Label-Printer-pd552585548.html

specification

| Article Name | Flame Retardant Cloth Label | Color | White | CODE | Flame retardant cloth label |

| Face Stock | Liner |

| Article Name | Polyamide Film | Article Name | 80gsm white glassine liner |

| Thickness(um) | 110±3 | Thickness(um) | 75±5 |

| Basic Weight(g/m2) | 70±3 | Basic Weight(g/m2) | 80±5 |

| Color | White | Color | White |

| Pressure Sensitive Adhesive |

| Properties | Value | Unit | Test Method |

| Thickness | 21±3 | um | GB/T 7125 |

| Dry Coating Weight | 21±3 | g/m2 | GB/T 7125 |

| Peel.Adhesive | 0.8↑ | Kg/in | GB/T 2792 |

| Release Force | 10±6 | g/in | GB/T 2791 |

| Initial Tack | 1~5 | # | GB/T 4852 |

| Holding Power | 8↑ | hr/kg*in | GB/T 4851 |

| Service Temperature | 5~125 | ℃ |

|

| Storage condition | The storage condition is at normal temperature, in a cool, ventilated and dry place (0 - 28 ℃, below 70%RH). Avoid high temperature and high humidity, and do not expose to the sun or rain. The best storage condition is 23 ± 5 ℃ and 65 ± 5%RH, and the shelf life is 12 months. (Note: If the product is stored for a long time at too high or too low temperature and humidity, the shelf life will be significantly shortened.) |

| Remark | The quality control of our company's products is inspected and controlled according to the product specifications listed in our product instruction manual. There will be differences in actual applications. Please make sure to understand the purpose, usage conditions and requirements before use, and conduct tests to confirm that there are no problems before use. Unless otherwise clearly agreed, our company will not bear the loss costs other than this material. |

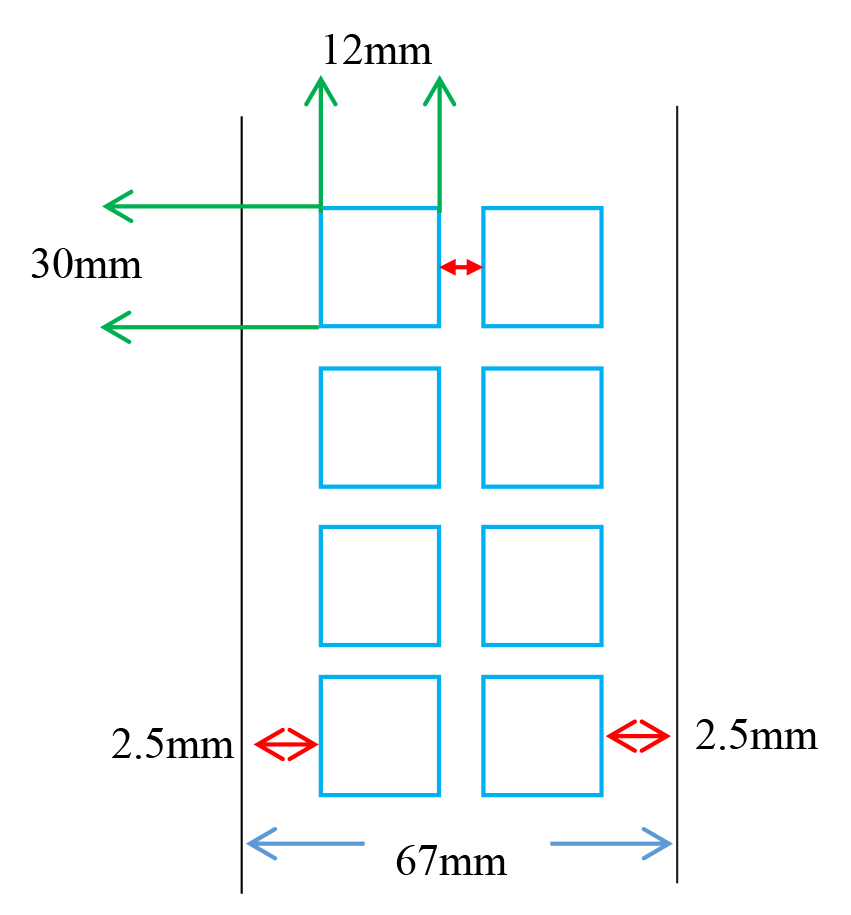

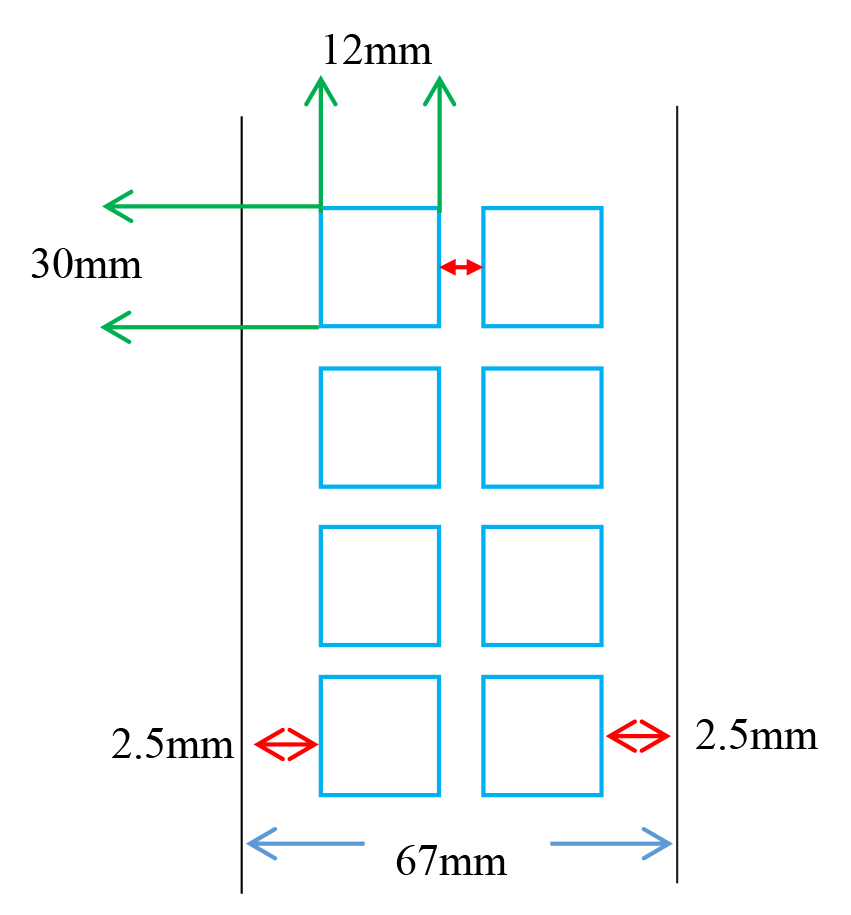

Dimensions

Material: Flame-retardant fabric label with checkered bottom

Specifications: 30mm*12mm double row R0.5 corner

Left and right margins 2.5mm, center spacing 2mm

Bottom paper width 67mm