Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Heat resistant labels are made with special materials like polyimide and aluminum foil. These materials help the labels survive very high heat, up to 600°F or more.

Strong adhesives and protective coatings help the labels stay in place. They also keep the labels clear, even with heat, chemicals, water, or scratches.

Thermal transfer printing uses resin ribbons to make tough labels. These labels are easy to read and do not fade or smear in hard places.

You must pick the right label for the temperature, surface, and job needs. Always test the labels to make sure they work well for you.

Certified brands like gaofei make heat resistant labels that meet safety rules. These labels help keep track of things and keep people safe at work.

Labels need to survive very hot places. Labels heat resistant to 600 degrees use special materials like polyimide. Polyimide does not melt or change shape in high heat. These labels keep their color and shape for a long time. The labels have layers that protect the printed words. These layers stop heat and chemicals from hurting the label.

The glue on these labels must stay strong in heat. Makers use glue that does not peel off in hot places. Protective coatings help keep the label safe. These coatings stop scratches, water, oil, and chemicals. You can count on these labels to stay clear and stuck, even in hard jobs.

Labels heat resistant to 600 degrees are used in many jobs. Workers put them on circuit boards, batteries, and inside cell phones. These labels are also on electrical and mechanical things. The labels must stay easy to read after heat, chemicals, and use.

It is important to know about short and long heat exposure. Some labels can take quick bursts of heat but not for a long time. Other labels can handle heat for a long time without changing. Pick the right label for your job.

When you need labels heat resistant to 600 degrees, look at brands like gaofei. Gaofei makes labels for electronics, metal work, and other hot jobs. Their labels are made to be strong and last long.

Heat-resistant labels must do more than handle heat. They also need to fight chemicals, water, oil, and wear. This helps the labels stay clear and stuck, even in tough places.

Polyimide is used for labels in hot places. It can handle heat up to 500°F. This material does not melt or change shape. You see polyimide labels in electronics and aerospace. They are also on circuit boards. These labels keep their color and words after heat. Polyimide is chosen because it resists chemicals and scratches. Brands likegaofei use polyimide for strong labels.

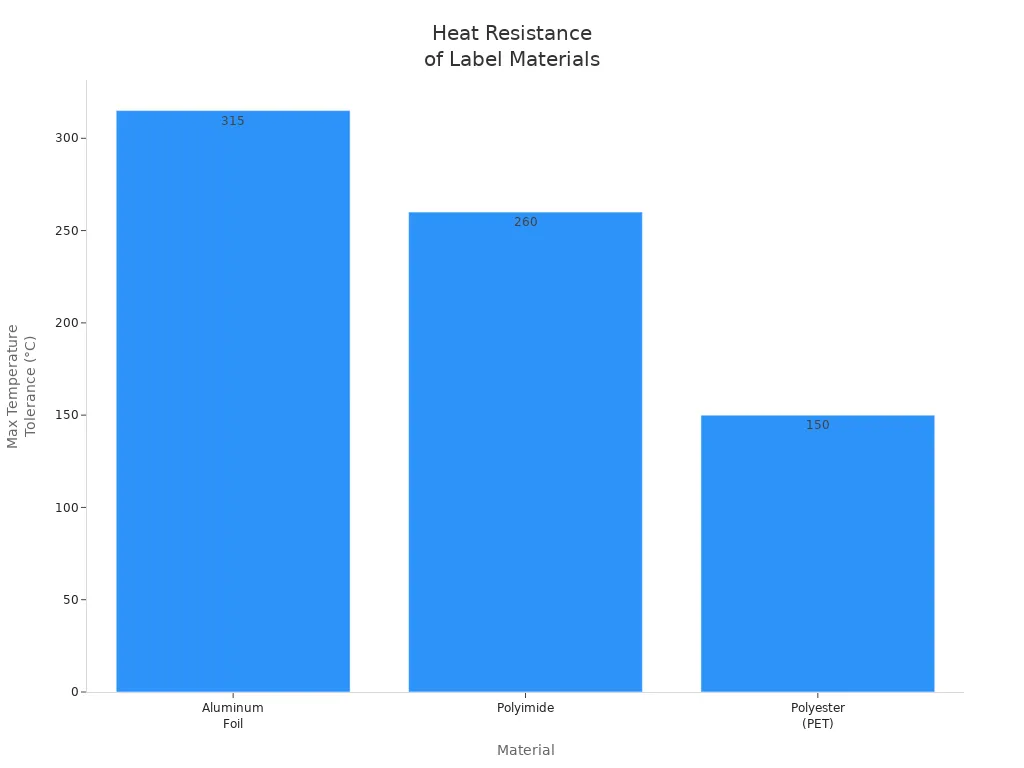

Aluminum foil labels work in very hot spots. They can take heat up to 600°F. You find these labels in aerospace and cars. They are also used in metal processing. Aluminum foil reflects heat and fights rust and weather. It also resists UV damage. These labels are light and do not mess with electronics. Aluminum foil is stiff and does not bend much. It may not fit curved surfaces. The table below shows how aluminum foil, polyimide, and polyester compare for heat resistance:

Material | Max Temperature Tolerance | Typical Industrial Uses |

|---|---|---|

Aluminum Foil | Up to 600°F (315°C) | Aerospace, automotive, high-heat mechanical parts |

Polyimide | Up to 500°F (260°C) | Electronics, PCB labeling, aerospace components |

Polyester (PET) | Up to 300°F (150°C) | General industrial labeling, asset tracking |

Tip: Pick aluminum foil labels when you need the most heat resistance and toughness.

Adhesives and coatings help labels last in hot jobs. Silicone-based, acrylic, and epoxy adhesives keep labels stuck in heat over 600°F. These adhesives do not melt or slide off. Protective coatings help labels fight scratches and bubbling. They also stop discoloration. Some labels have ceramic coatings for extra protection. These coatings help with chemicals and heat. Labels from brands like gaofei use strong adhesives and coatings. This helps labels last through heat, chemicals, and wear.

You need good printing for heat resistant thermal transfer labels. Thermal transfer printing uses a ribbon with ink on it. The printer heats the ribbon, and the ink melts onto the label. This makes clear pictures that last a long time. The images do not fade or smear, even in hard places. Direct thermal printing does not use a ribbon and needs special paper. Thermal transfer printing works with more materials. You can use it on polyimide, polyester, or aluminum foil labels. This is great for labels in factories, labs, and outside.

Pick resin ribbons for the best results. Resin ribbons work well with heat resistant thermal transfer labels. They can handle high heat, chemicals, and scratches. Printers like the Zebra ZD620T or CAB SQUIX4 use resin ribbons. These printers make labels that are easy to read and strong. The table below lists some good printers and ribbon types:

Printer Model | Ribbon Type | Features and Suitability |

|---|---|---|

GAOFE TR4032B | Resin Ribbon | Industrial, high temperature, chemical resistant |

GAOFE TR4081 | Resin Ribbon | High resolution, smudge and alcohol resistant |

Resin Ribbon | Durable, heat resistant, suitable for industry |

Tip: Use resin ribbons with polyimide or PET labels for the strongest labels.

You want your heat resistant thermal transfer labels to stay easy to read. They should not change after heat, water, or chemicals touch them. The ink comes from special ribbons made for high heat. Resin-based inks stick well to the label. This keeps the print safe from scratches, smears, and strong cleaners. UV flexo inks also give bright color and good print when hot.

Heat-resistant labels printed this way keep their words clear. They work well in tough places. You can use these labels for tracking parts, safety signs, or keeping track of items. Other labels might not last, but these do.

Labels are very important in steel and metal plants. Workers use them to mark steel slabs and rolls right after they are made. The metal is still hot at this time. These labels must stick to metal and not fall off. They also need to survive strong chemicals used for cleaning. Some labels, like RFID-enabled self-laminating ones, use special glue and covers. This helps the labels stay on and easy to read, even when it is very hot. For example, ThyssenKrupp uses smart labels to track hot steel slabs. This makes unloading faster and keeps workers safer. Metalphoto anodized aluminum labels can take heat up to 1200°F. They also do not scratch, rust, or get ruined by chemicals. You can use these labels for tracking, safety signs, and keeping inventory in tough places.

Electronics factories need labels that can handle high heat. Solder reflow and wave soldering get very hot, up to 300°C. Polyimide labels with strong glue stay stuck and clear during these steps. You can print on these labels with thermal transfer and resin ribbons. This keeps barcodes and words easy to read. These labels help you track circuit boards and parts without changing them. They work even after ovens and cleaning chemicals. Brands like gaofei make labels for electronics. This helps you keep track of parts from start to finish.

Ceramics jobs also need labels that can take heat and chemicals. In ceramics, labels go through kilns and must not shrink or peel. Makers use polyimide and special glue to stop labels from changing shape. This keeps the writing clear. Protective coatings help labels fight water, rust, and strong chemicals. You can trust these labels to stay on and easy to read, even after lots of heat and cleaning.

You need to know how hot your process gets. Pick a label that matches the highest temperature. Here is an easy guide:

Polyester (PET): Works up to 400°F. It is good for medium heat and bends on curved surfaces.

Polyimide: Handles up to 600°F. It is used in electronics, aerospace, and cars.

Silicone: Stays strong from 500°F to 600°F. It bends easily and does not get ruined by water or sunlight.

Ceramic-Coated Labels: Can take over 1000°F. They are used in big factories.

Tip: Always check the temperature range for your job. If you work with very high heat, polyimide or ceramic-coated labels from brands like gaofei protect best.

The place you stick the label matters. Clean and smooth surfaces help glue stick better. Dirty or rough places make the label weaker. Remember these points:

Rubber-based adhesives stick well to rough surfaces.

Acrylic adhesives work on glass, metal, and plastic. They stay strong in hot and cold places.

Silicone adhesives work in high heat and when pressure changes.

Test labels in real life. Try peel and pull tests to see if the label stays. Always clean the spot before you put on the label.

You need to follow safety and work rules. Labels must meet standards like UL, RoHS, NASA, or military codes. Some labels, like Metalphoto or gaofei, have certificates for USDA, FDA, or other groups. These labels work in ovens, dishwashers, and factories. Look for labels that give you:

Certificates that show they follow rules

Help from experts and a warranty

Proof they work for your job

Note: Using certified labels helps you pass checks and keeps your workplace safe.

Picking the right labels for hot places helps keep everyone safe and work easy. You should know about materials like polyimide and glues like silicone. These help labels stick well in heat. Printing with thermal transfer makes labels easy to read, even when things get tough. Some brands, like gaofei, make strong labels for hard jobs.

You should test your labels often for how well they stick, fight chemicals, and last. Check what labels you need as your work changes.

Check the product details for heat ratings. Look for certifications like UL or RoHS. Brands like gaofei show heat resistance on their labels. Always test a sample in your workspace before using it.

Yes, you can print barcodes with thermal transfer printers. Use resin ribbons for the best results. The print stays clear after heat, chemicals, and cleaning.

Smooth and clean surfaces help labels stick better. Metal, glass, and some plastics work best. Always clean the spot before putting on the label. Rough or dirty spots can make the label weaker.

Most heat resistant labels fight chemicals, water, and oil. Polyimide and aluminum foil labels give strong protection. Protective coatings make them last longer. Always check the label details for chemical resistance.

Gaofei labels use special materials and glue. You get good results in very hot places. These labels stay easy to read and stuck, even in hard jobs.