Overview

Designed for the demanding automotive and transportation industry, B-536G Vulcanized Tire Labels are engineered for permanent identification through the tire curing process. These specialty labels withstand extreme heat and pressure during vulcanization while maintaining excellent adhesion to rubber surfaces. Featuring oil resistance, flexibility, and durable print retention, they enable reliable tracking of tires throughout their lifecycle—from manufacturing to retreading and final use.

Feature

1. Exceptional High-Temperature Vulcanization Resistance

These labels are engineered to withstand tire curing temperatures above 180°C. Made with heat-resistant materials, they integrate permanently during vulcanization without melting or failing.

2. Permanent Chemical Bonding with Rubber Substrates

They form a chemical bond with rubber during vulcanization, fusing into the tire structure. This ensures lifelong adhesion that resists peeling, even under flexing and thermal stress.

3. Superior Durability in Harsh Service Environments

Resistant to oil, ozone, abrasion, and UV exposure. Printed information stays protected against weather and chemicals, remaining scannable throughout the tire's service life.

Application :

Factory Identification During Tire Production & Vulcanization

Applied directly onto the tire sidewall or casing before curing, these labels are integrated into the tire during high-pressure vulcanization. They carry unique serial numbers, production batches, specifications, and DOT codes, enabling precise traceability and quality control from the point of origin.

Lifecycle Tracking for Retreaded Tires

Used during the retreading process, the labels are bonded to the tire casing and undergo a second vulcanization cycle. They preserve the original tire data while recording retread history, process standards, and retreader information, supporting compliance and value management for commercial tire "casing life tracking."

Optimal Printing Solutions

Recommended Ribbons:

GAOFE TR4133 Vulcanized Resin Ribbonhttps://www.dggaofe.com/GAOFE-TR4133-Resin-Ribbons-for-Vulcanized-Labels-Reliable-Long-Lasting-pd557183948.html

Superior Temperature Resistance,Withstands continuous exposure to 200°C+ environments

Exceptional Adhesion Performance,Achieves ≥3N/inch bond strength post-vulcanization

Recommended Printer

Zebra ZT610 Industrial Printer (600DPI)

1.Wide Thickness Compatibility:

Supports labels from 0.06–0.51mm, ideal for thick vulcanized labels (typically 0.2–0.4mm), preventing jams or print pressure issues.

2. 600DPI Ultra-High Resolution:

Delivers crisp text, high-density barcodes

3.Fast Printing Without Compromise:

Up to 14 IPS (356 mm/s) speeds maintain efficiency for bulk tire label production.

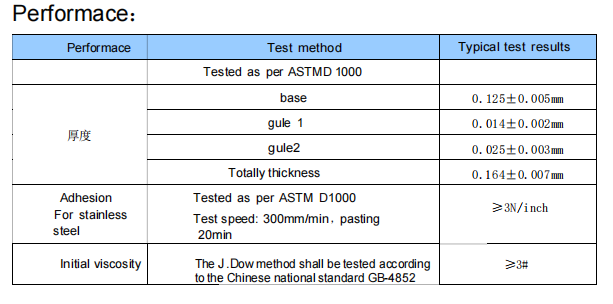

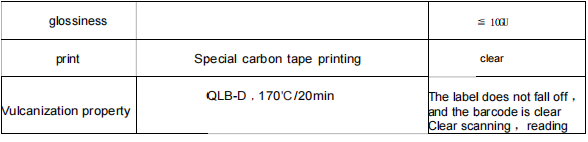

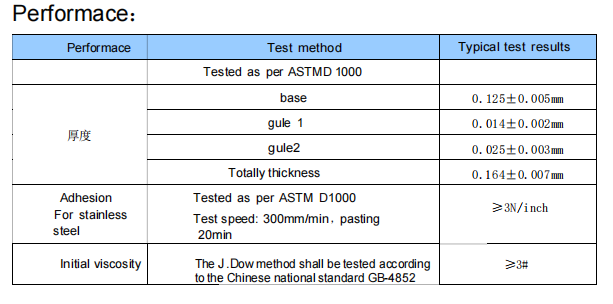

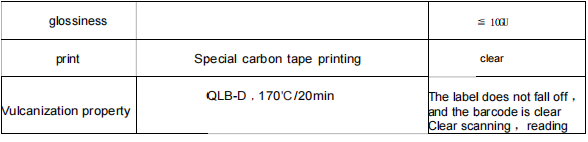

Specification