Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

Picking the right high temperature label supplier is important. It helps keep things working in electronics, manufacturing, and logistics. These areas need labels that last and can handle chemicals.

Key industry trends that affect suppliers:

More cars and planes need labels that can take a lot of heat and chemicals.

Strong materials like polyester and polycarbonate help labels last longer.

Electronics and factories need labels for rules and tracking.

Digital printing and new adhesives make labels stronger and more unique.

Asia Pacific, North America, and Europe are growing fast in this industry.

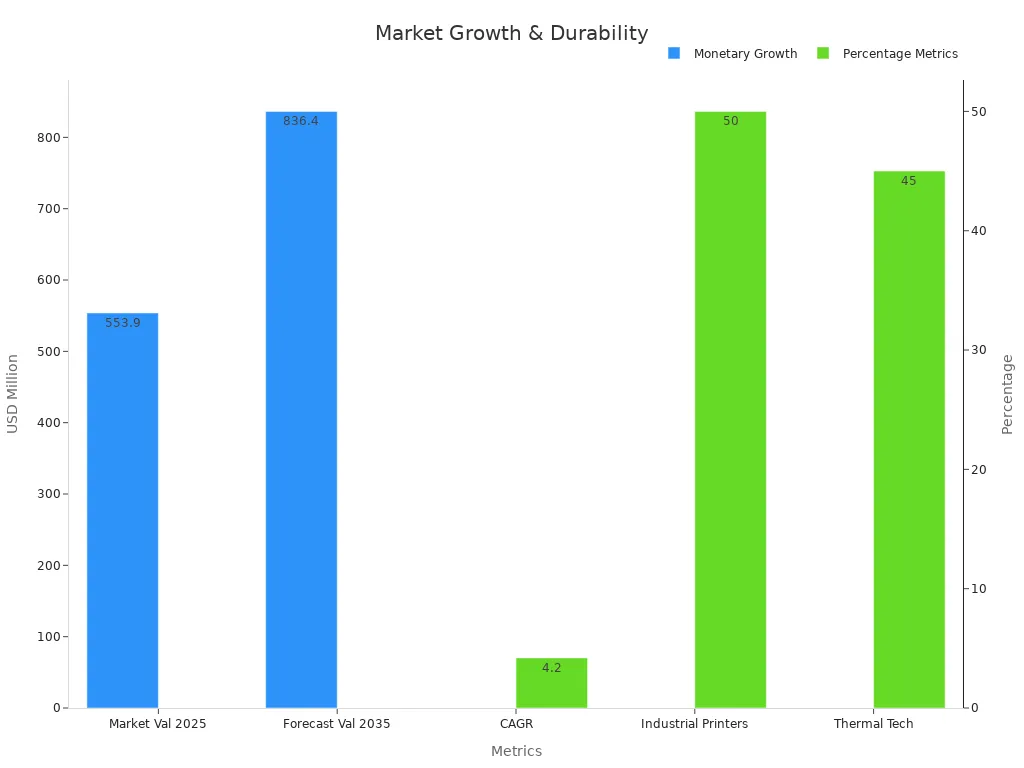

| Metric | Value | Explanation |

|---|---|---|

| Market Value (2025) | USD 553.9M | This shows how big the high temperature label market is. |

| Forecast Value (2035) | USD 836.4M | This shows how much the market could grow in ten years. |

| Compound Annual Growth Rate | 4.2% | This means the industry is growing at a steady rate. |

| Industrial Label Printers Share | ~50% | This shows many people want strong labels. |

| Thermal Printing Technology | >45% | This means most high-resistance labels use thermal printing. |

| Fastest Growth Region | USA (4.2% CAGR) | This shows the USA is growing fast because of tech and rules. |

Supplier profiles and the table below help people choose the best solution for their needs.

Why choose with Us?

Expertise & Innovation

Over 17 years of experience in label, printing system and RFID technology

Provide high-performance label solutions such as high temperature (300°C+), low temperature (-196°C) and vulcanized special labels

Advanced Integration

Excellent in combining cutting-edge technology with practical applications

Thermal transfer ensures durable printing, RFID and automatic labeling systems improve inventory management accuracy and production efficiency

Uncompromising Quality

Products include steel mechanical labels, tamper-proof security labels, etc.

Strictly tested and in compliance with international standards, widely used in manufacturing, logistics and medical industries

• Specialty environment labels: High-temperature resistant (up to 1200°C), anti-vulcanization, and ultra-low temperature liquid nitrogen labels (-196°C)

• Printing systems: Industrial-grade printers, medical tube labelers, and automated labeling equipment

• Printing consumables: Chemical-resistant ribbons and medical solvent-proof printing materials

• Software systems: UDI compliance management systems, product traceability platforms, and ERP integration modules

• Liquid nitrogen-resistant tube labels

• Color-coded specimen management systems

• Solvent-proof printing (resistant to isopropanol, propanol, methanol, etc.)

• Medical device tracking: Sterile packaging to implantable device serialization

SMT traceability systems:

• Automated PCB labeling with unique QR codes

• Real-time ERP-to-production data flow

• 30-second defect tracin

High-durability solutions:

• Oil-resistant engine compartment labels

• Tire identification for vulcanization processes

• Paint shop oven-resistant labels

• Smart labeling: RFID tracking for JIT production

• Automated labeling systems: High-speed labeling for boxes/pallets

• Cold chain solutions: Labels for humid/freezing environments

• Temporary identification: Residue-free removable labels

The high temperature label market is getting bigger. This is because more people need labels in electronics, cars, and factories.

Many companies now make eco-friendly labels. They use recycled stuff and plant glues to help the planet.

Picking the best supplier means you look at how tough the label is. You should also check for certifications like UL and RoHS. Good customer support is important for your needs.

Custom labels can have barcodes, RFID, and sticky glue. These help businesses track things and stay safe in hard places.

Each business needs different temperature-sensitive labels. First, companies should think about where they will use the labels. Some labels must handle very high heat. Others need to stand up to chemicals or water. It is smart to look at all the ways labels will be used before picking one. For example, electronics makers need labels that do not fall off during soldering. Shipping companies want labels that stay clear when moving boxes.

Decide the temperature and conditions for the labels.

See if labels must handle cleaning or strong liquids.

Think about how labels will be moved or stored.

Use tools to check if labels work in real life.

Ask if the supplier can make special labels for hard jobs.

Companies that use good cold chain rules and plan for risks can save money and avoid problems with heat-resistant labels.

Certifications prove a supplier follows important rules. Labels for some jobs must pass hard tests. Companies should pick suppliers with certifications like UL, RoHS, or FDA. The UL program checks if labels are safe and work well. Suppliers in these programs usually make better labels.

Find out if the supplier has UL 969A for safety.

Check if ink and glue have special certificates for tough jobs.

Make sure the supplier follows FDA and EC rules for records.

Ask if the supplier gets checked and follows written steps.

Certified suppliers help companies follow the law and avoid trouble.

Support and price matter when picking a supplier. Companies should see how fast suppliers answer questions and help with problems. Good suppliers give training, clear guides, and ship orders quickly. The price should fit the label’s strength and features.

Compare how fast and helpful customer service is.

Look at training and help the supplier gives.

Check if the price matches how long labels last.

Think about what you get for your money over time.

A high temperature label is made from special stuff like polyimide or polyester. These labels do not melt or fall off when it gets really hot. Many businesses use them to keep track of things and stay safe.

Suppliers put labels in ovens and dip them in chemicals. They also wash them many times. They look to see if the labels fade, peel, or stop sticking. Labs with special certificates often do these tests.

Certifications like UL or RoHS show that labels are safe and good quality. These papers help companies follow the rules. They also help stop big mistakes that cost a lot of money.

Yes. Many suppliers now have green choices. These labels use recycled stuff or glue from plants. Companies pick them to make less trash and help the earth.

Tip: A business should look at how strong the labels are, if they have certifications, and what help and prices they offer. Asking for samples and reading reviews helps make sure the supplier is a good fit.