Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

Pharmaceutical labeling is more than just a legal requirement; it's critical to patient safety and drug efficacy. Labels provide vital information on medication use and potential risks, ensuring the right treatment is delivered.

In this article, we will explore why pharmaceutical labeling matters, from compliance with regulations to enhancing patient safety. We’ll also discuss the role of industrial labels in maintaining accuracy and meeting global standards.

Accurate labeling is directly linked to patient safety. Labels provide essential information about the correct dosage, usage instructions, potential side effects, and contraindications. Without clear instructions, patients risk misusing the medication, which can lead to harmful outcomes. Mislabeling a drug can result in life-threatening consequences, including overdose, adverse reactions, or failure to treat the intended condition.

For example, a study found that incorrect drug labeling was a significant contributor to medication errors in healthcare settings, leading to unnecessary hospitalizations and healthcare costs. To mitigate such risks, pharmaceutical companies use industrial labels that are standardized to ensure that healthcare providers can easily interpret the medication’s instructions and make informed decisions.

Regulatory bodies like the FDA (U.S. Food and Drug Administration) and EMA (European Medicines Agency) require pharmaceutical companies to adhere to strict labeling guidelines. These regulations are designed to protect consumers, ensure the safe use of drugs, and maintain public health standards. Labels must include detailed information about the drug, such as its composition, dosage instructions, expiration dates, and storage conditions.

Compliance with these regulations not only ensures the safety of patients but also helps pharmaceutical companies avoid costly fines, product recalls, and potential legal issues. Industrial labels play a critical role in maintaining compliance by providing standardized formats that align with global regulatory requirements.

Pharmaceutical labeling also serves as a bridge between manufacturers, healthcare providers, and patients. Clear and accurate labels help build trust, as patients and healthcare providers rely on them for crucial information about the medication's intended use, safety profile, and potential side effects. This transparency reduces the likelihood of errors and fosters a more reliable healthcare environment.

When a drug is properly labeled, healthcare professionals can quickly identify it, understand its uses, and provide patients with the best possible care. This trust is critical in the healthcare industry, where the consequences of mistakes can be severe.

| Topic | Importance and Benefits |

|---|---|

| Pharmaceutical Labeling | Ensures patient safety, regulatory compliance, and correct medication use. |

| Role of Industrial Labels | Standardizes labeling to minimize errors, enhancing patient safety and regulatory adherence. |

| Legal Consequences of Errors | Incorrect labeling can lead to fines, recalls, and damage to company reputation. |

| Digital Labeling Solutions | Reduces manual errors, ensures real-time updates, and boosts operational efficiency and regulatory compliance. |

The primary label on pharmaceutical packaging serves as the first point of contact for healthcare professionals and patients. This label typically includes the drug's name, active ingredients, dosage form (tablet, injection, etc.), strength, and usage instructions. Additionally, it often includes storage instructions, expiration dates, and the manufacturer’s contact details.

The industrial labels used in pharmaceutical packaging are carefully designed to meet regulatory requirements and ensure legibility. They must be printed in a way that resists smudging or fading, ensuring that the information remains readable throughout the shelf life of the product.

In addition to primary labels, healthcare providers often require more detailed information, especially for prescription drugs. This includes prescribing information (PI), patient package inserts (PPI), and medication guides. These documents provide in-depth details about the drug, including contraindications, detailed dosage instructions, and the management of side effects.

For example, a drug that is prescribed for a specific population, such as children or pregnant women, will have additional labeling to provide instructions on safe usage for those groups. These in-depth labels are essential for ensuring that healthcare professionals can make the most informed decisions when prescribing medications.

Certain populations, such as children, elderly individuals, and pregnant women, may require specialized labeling. These labels highlight potential risks and provide tailored instructions to ensure safe use. Special labels may also include Braille or multilingual translations to cater to a diverse range of patients.

For instance, a label may specify that a medication is not safe for use during pregnancy or provide warnings for elderly patients who may be more susceptible to side effects. These tailored labels help ensure that vulnerable groups are properly protected when using pharmaceutical products.

Correct dosing is crucial for the efficacy of any medication. Labels must clearly state the recommended dosage, the frequency of administration, and the method of intake (oral, injection, etc.). Mislabeling or unclear dosage instructions can lead to underdosing or overdosing, both of which can severely impact the drug’s effectiveness.

For instance, an incorrect dosage instruction can reduce the therapeutic effect of a drug or, in the case of an overdose, lead to harmful side effects. Accurate dosing instructions are vital for ensuring that the drug performs as intended and delivers the desired therapeutic outcome.

Pharmaceutical labeling errors can have serious consequences, including accidental overdose or misuse of the drug. In some cases, these errors may be fatal. Labeling mistakes often arise from human error during the design, printing, or packaging stages, which is why industrial labels are closely regulated and subjected to strict quality controls to minimize these risks.

An example of such a mistake occurred when a pharmaceutical company misprinted the dosage instructions on a widely used painkiller. The result was a significant number of overdose cases, leading to product recalls and a tarnished reputation. This underscores the critical importance of precision in pharmaceutical labeling.

Labels also play a crucial role in preventing harmful drug interactions. By providing information about contraindicated drugs, potential drug interactions, and the risks involved, labels help healthcare professionals avoid prescribing medications that could interact negatively with one another.

For example, labels often contain warnings about combining certain drugs with alcohol, or using a drug in conjunction with another medication that may reduce its effectiveness. These precautions are essential for ensuring that drugs do not produce harmful or unintended side effects when taken together.

Pharmaceutical companies can face significant legal liabilities if their products are mis-labeled. These liabilities may result in lawsuits from patients who experience harm due to incorrect labeling, or from healthcare providers who fail to provide appropriate care due to missing or inaccurate information.

For example, if a drug is incorrectly labeled as safe for a certain group of people when it is not, the company could be held liable for any harm caused. Therefore, pharmaceutical companies must ensure that their labels are thoroughly reviewed and compliant with regulations to avoid legal consequences.

Failure to comply with labeling regulations can lead to hefty fines, product recalls, and even the suspension of market approval. Pharmaceutical companies must continually update their labels to reflect new clinical data, regulatory changes, or safety concerns, and any delay in doing so could result in non-compliance.

In addition to the legal costs, non-compliance can damage a company’s reputation and brand value. Patients and healthcare providers rely on accurate labeling, and errors can lead to a loss of trust in the company’s products.

In cases of severe negligence or deliberate mislabeling, pharmaceutical companies and their executives could face criminal charges. These violations may include falsifying labeling information or intentionally hiding safety risks, which can result in criminal penalties, including fines and imprisonment.

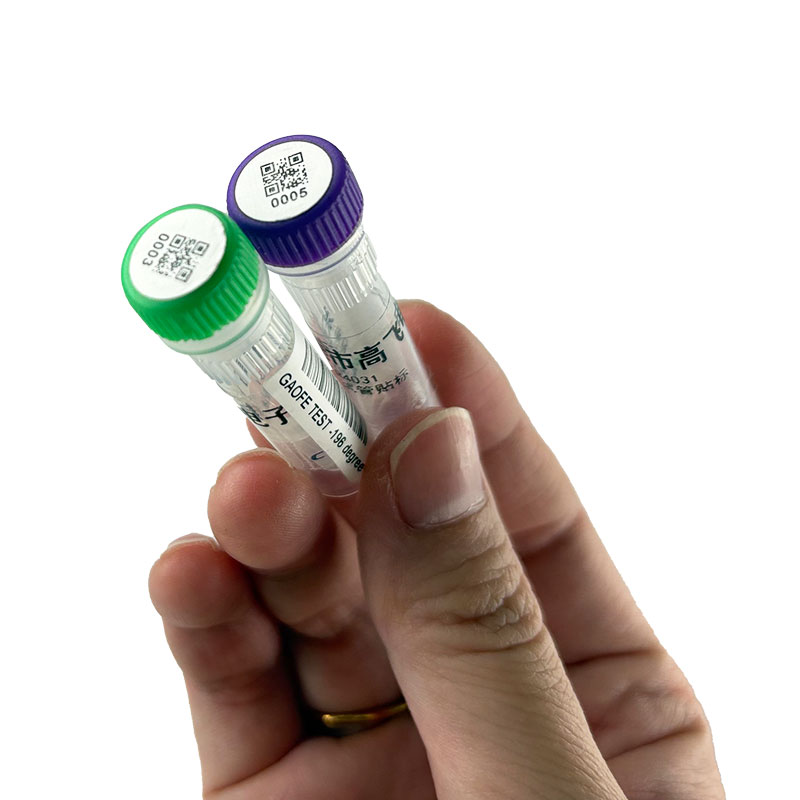

The pharmaceutical industry is increasingly adopting e-labeling, which replaces traditional paper-based labels with digital solutions like QR codes, RFID tags, and electronic labeling platforms. These digital formats offer several advantages, such as real-time updates, improved accuracy, and better accessibility.

For example, patients can scan a QR code on a medication to access up-to-date information on dosage instructions, potential side effects, and drug interactions. This real-time information helps reduce errors and ensures that both patients and healthcare professionals have access to the most accurate data.

Global regulatory bodies are gradually accepting digital labeling formats, which offer better compliance tracking and efficiency. For instance, the FDA has approved the use of electronic labeling for certain pharmaceutical products, streamlining the approval process and improving product traceability.

Digital labels also allow for faster updates to be disseminated across supply chains, reducing the risk of outdated information being circulated. As e-labeling becomes more widespread, pharmaceutical companies will need to adapt to these digital solutions to stay competitive.

One of the key benefits of digital labeling is the ability to provide real-time updates. This ensures that patients, healthcare providers, and regulatory bodies are always in sync with the latest information about a drug. Digital systems can integrate seamlessly with existing databases, ensuring that any changes in labeling (e.g., drug recalls or new safety information) are instantly reflected across all platforms.

To ensure the accuracy and consistency of pharmaceutical labels, companies must follow industry-standard labeling techniques. These standards ensure that labels are compliant with regulatory requirements, clear, and easy to understand.

Automated proofreading systems play a crucial role in minimizing human error in the labeling process. By using software that can detect inconsistencies, spelling mistakes, or formatting errors, pharmaceutical companies can significantly reduce the risk of mislabeling and improve the overall quality of their labels.

Pharmaceutical companies operating globally must ensure that their labels comply with the varying regulations in different countries. This requires a deep understanding of local laws and an efficient system for managing and updating label content across markets.

Pharmaceutical labels are vital for patient safety, regulatory compliance, and drug efficacy. Accurate labeling ensures medications are used correctly and provides healthcare professionals with essential information. As the industry evolves, digital labeling solutions improve efficiency, compliance, and safety.

Pharmaceutical companies must prioritize labeling to reduce risks, avoid legal issues, and maintain trust. For those aiming to stay ahead, transitioning to digital labeling systems ensures compliance and boosts efficiency. GAOFE offers products that meet these needs, enhancing the labeling process for pharmaceutical companies.

A: Labeling ensures patient safety, regulatory compliance, and proper drug usage. It provides essential information for healthcare providers to administer medications correctly.

A: Industrial labels standardize information, reducing the risk of errors and ensuring medications are used correctly, which is critical for patient safety.

A: Incorrect labeling can result in legal liabilities, fines, product recalls, and damage to a company’s reputation. Accurate labeling is essential for compliance.

A: Digital labeling reduces manual errors, ensures real-time updates, and helps companies stay compliant with evolving regulations, improving overall efficiency.