Overview

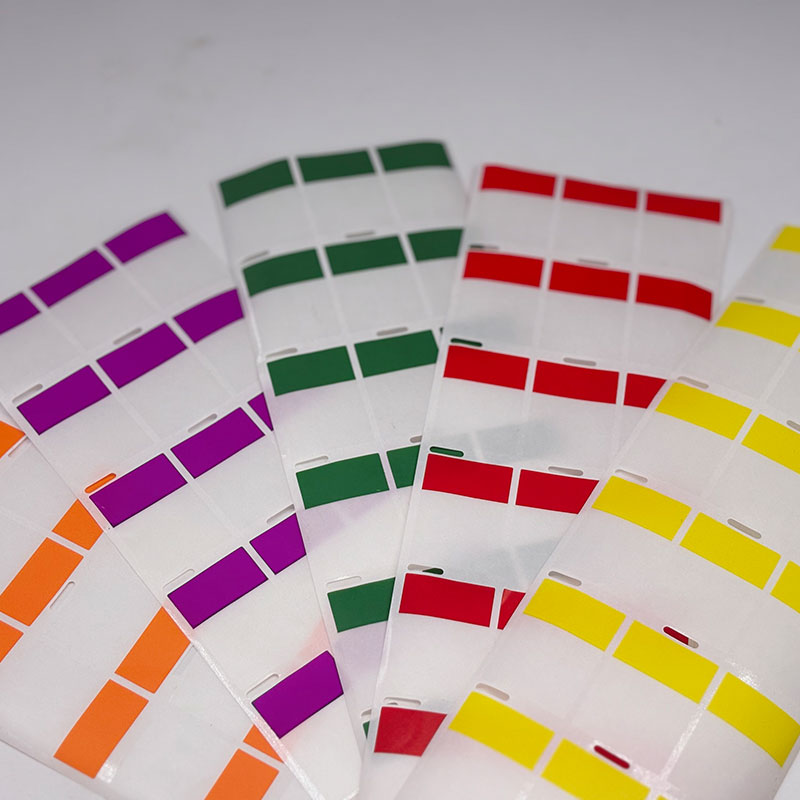

The B-674G PVC cable wrap-around label is specifically designed for Data Center and Communication Systems, providing reliable and long-term cable identification in high-density server and network environments.

As a professional-grade solution within Data Center and Server Labels, this PVC label is engineered to wrap tightly around cables, forming a clear and durable identification surface without edge lifting or flagging. Its flexible Polyvinyl Chloride (PVC) construction ensures stable performance on Ethernet cables, power cords, patch cords, and communication lines commonly used in data centers and server rooms.

Features

Durable PVC (Polyvinyl Chloride) Material

Offers excellent flexibility, abrasion resistance, and mechanical strength for continuous use in data center environments.

Wrap-Around Cable Identification Design

Designed to wrap and overlap on itself, creating a secure bond ideal for round cables and high-density cable bundles.

Optimized for Data Center and Server Labels

Maintains legibility and adhesion in server racks, cabinets, and communication closets.

Clear Print Performance

Supports barcode, alphanumeric codes, port numbers, and network identifiers for accurate cable tracing.

Reliable Adhesion for Communication Systems

Adheres firmly to common cable jackets without slipping, curling, or detaching over time.

Application

Data Center Cable Management

Used for identifying Ethernet cables, power cables, and patch cords in server racks and cabinets.

Communication Systems Identification

Ideal for structured cabling systems in telecom rooms, network operation centers, and communication hubs.

Server Room & Rack Labeling

Supports efficient maintenance, troubleshooting, and expansion in complex server infrastructures.

Network Infrastructure Projects

Suitable for new installations, upgrades, and retrofitting of data center and communication systems.

Optimal Printing Solutions

Recommended Ribbon

Recommended Printer

Other Options

| NO. | Name | Model |

| 1 | Fold cable label

| B-678G

|

Constitute

Specification

physical characteristics | test method | Average test results |

thickness | ASTM D1000 Testing -Vinyl substrate -Pressure-sensitive adhesive -Off-form paper -amount to |

0.06 mm 0.023 mm 0.074 mm 0.16 mm |

Paste to: -stainless steel | ASTM D1000 Testing

Paste for 20 minutes Stick for 24 hours |

≥1900gf/inch ≥2000gf/inch |

-Initial adhesion -Hold adhesion | ASTM D2979 Testing ASTM D3654 Testing | 430g 310g(18.7oz) |

-light transmittance | ISO7686:2005 | 90% |

-fog level | ISO7686:2005 | 45% |

insulativity | ASTM D1000 Testing | 6000V |

inflammability | ASTM D1000 Testing Average burning time | Less than 10 seconds |

Function test method:

Use TR4032B series black color strip heat transfer printing sample tape.

function | test method | test result |

Maximum adaptation temperature | 70°C for 30 days | has/have no influence |

Maximum adaptation temperature | -40°C for 30 days | has/have no influence |

Moisture resistance | 37 ° C (100 ° F), relative humidity 95% for 30 days | has/have no influence |

ageing resistance | 30 days xenon arc aging test machine, one cycle | has/have no influence |

Chemical test

chemical reagent | Visual observation affects |

Base material/adhesive | carbon tape |

Cleaners and solvents |

|

|

isopropanol | No visible effects | No visible effects |

mineral spirits | No visible effects | No visible effects |

Northwoods TM Buzz Saw Terpene Cleaner | No visible effects | No visible effects |

deionized water | No visible effects | No visible effects |

Fuel, oil and lubricants |

|

|

gasoline | Slight lifting | No visible effects |

brake fluid | No visible effects | No visible effects |

SAE 30 WT Oil at 70°C | No visible effects | No visible effects |

Yellow 77 Lubricating oil | No visible effects | No visible effects |

Aerospace liquids |

|

|

JP-8, space fuel | No visible effects | No visible effects |

Skydro 500B-4 | Material damage | NA |

MIL-H-5606 | No visible effects | No visible effects |

Unless otherwise noted, tests are performed after 24 hours at room temperature. The test consists of five cycles, soaking in the specified test fluid for 10 minutes, then removing and placing for 30 minutes before testing. B-674G is not recommended for use in harsh organic solvents such as methyl ethyl ketone, acetone, or 1,1,1-trichloroethane.

Term of validity

The product can be stored for at least 1 year (from the date of receipt) in an unopened environment with room temperature 15 ° C-23 ° C and relative humidity 60%.